| |

|

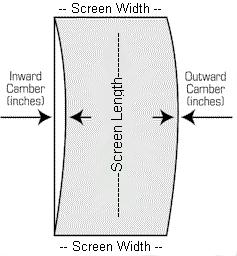

If unbalanced warp

tensions exist in a woven wire screen, that

screen will usually assume a "crescent" or

"banana" shape when laid flat upon a horizontal surface. This deviation

from a straight line is hereby defined as "camber."

|

| |

| To measure

screen camber, it is recommended that

the screen be unrolled on a flat surface. Next, one end of the

screen should be grasped (and one end only), then

tensioned in a straight line for some

distance to relax stresses imparted by handling and

shipping. At this point, the screen should lie flat.

Unequal and unresolved warp tensions in the screen will cause it to assume a

"crescent" or "banana" shape. |

| |

| Camber is measured by drawing a taut line along one

edge of the screen (inward camber edge) and measuring maximum deviation from that taut line

to the screen at the center point of that line.

|

|

|

Compute percent camber as

follows:

|

| |

|

% Camber =(Maximum Deviation)

/ (Length of

Screen) x 100

|

| |

|

Currently, there is no accepted Camber standard in the

U.S. market. For a maximum acceptable camber relative to a given

screen specification, please contact your

screen manufacturer. |

| |

| Camber can be instilled into a

screen during the slitting

operation if one of the slitting knives is dull. A dull slitting knife will tear the

fill wires (crosswise or "shute"

wires) rather than cut them. (While the

screen is in roll form,

the side of the screen which has gone through the dull knife will exhibit a

"ragged" appearance due to the torn/stretched

fill wires.) Usually, this type of

camber will be less than 1/2 of 1% and can be pulled out handily when the

screen is properly

tensioned. |

| |

| Skew (Bow) |

| |

|

The fill wires

(horizontal wires) in the

screen will usually lie along the perpendicular to the

screen center line. Any deviation from this perpendicular by the fill

wires is hereby

defined as "skew" or "bow."

|

| |

| A skewed pick in a plain

(or square), weave is cause for

concern since it is generally indicative of unbalanced warp tensions and will usually go

hand-in-hand with a significant camber. |

| |

|

[Technical Reference

Index]

[Woven Wire

Main Index]

[Wire

Cloth Products] |

| |

|

Screen Technology Group, Inc |

|

33008 NE Washougal River Road, Washougal

WA 98671 USA |

| |

|

Screen Technology Group,

established in 1988 With our success built on

providing a level of customer service that is

second to none, competent technical assistance,

quality materials at competitive prices,

properly package every order, always ship

promptly according to schedule. |

| |

|

By using this website, you are agreeing that you

have read and accepted the

Terms of Use Agreement |

|

Copyright © 2015

Screen Technology Group, Inc.

All Rights Reserved.

|

Last modified:

July 09, 2017 |

|